Laser Cutter vs Cricut: Best Machine to Cut Wood, Fabric or Metal?

Trying to craft an artistic piece for a commercial project? But figuring out which tool can bring your design to life? Laser cutter vs cricut, which one should you choose?

You want clean edges, precise design and an easy-to-use procedure, & want the best machine for that. Well, our years of experience in design & fabrication tell us that there’s no universal answer to “which is better?”

Each machine has its own pros and cons, and which one suits you better depends on your needs. You need a proper comparison before deciding & that’s what we’ve prepared for you.

Give it a read and then decide which is the best machine to cut designs in wood, paper, fabric or any material you’re dealing with.

How a Laser Cutter Engraver Works?

A 3d laser cutter is the professional cutting machine for upscale designing projects.

It works by directing a powerful laser beam onto your chosen material. The energy from the beam melts, burns or vaporises the material along the programmed path, and create neat & intricate designs.

The laser’s accuracy beats the blades in giving a consistent finish for industrial or complex work. Plus, the materials ranges from wood & acrylic to metal and more. At United Metal Laser, our laser cutting machines handle even pipes and tubes for precise shapes.

Businesses and professionals prefer the laser cut machine due to its speed & minimal waste.

Also Read: Beginner Guide to 3D Laser Cutting: Process, Uses & Benefits

How the Cricut Machine Works?

On the other hand, cricut machines work as a gadget for hobbyists and craft enthusiasts.

They use a small, super-sharp blade that glides over your chosen material. It can be vinyl, paper, cards, fabrics and even thin leather. Connected to your computer, the Cricut software plots your design and translates it into clean & precise cuts.

It doesn’t do heavy-duty work with tough material. But it gives you more control for the personalised items and handle small batch jobs with impressive accuracy. Plus, it doesn’t use heat so heat sensitive materials go well with it.

Beginners or home crafters prefer it for its simplicity and ease of use.

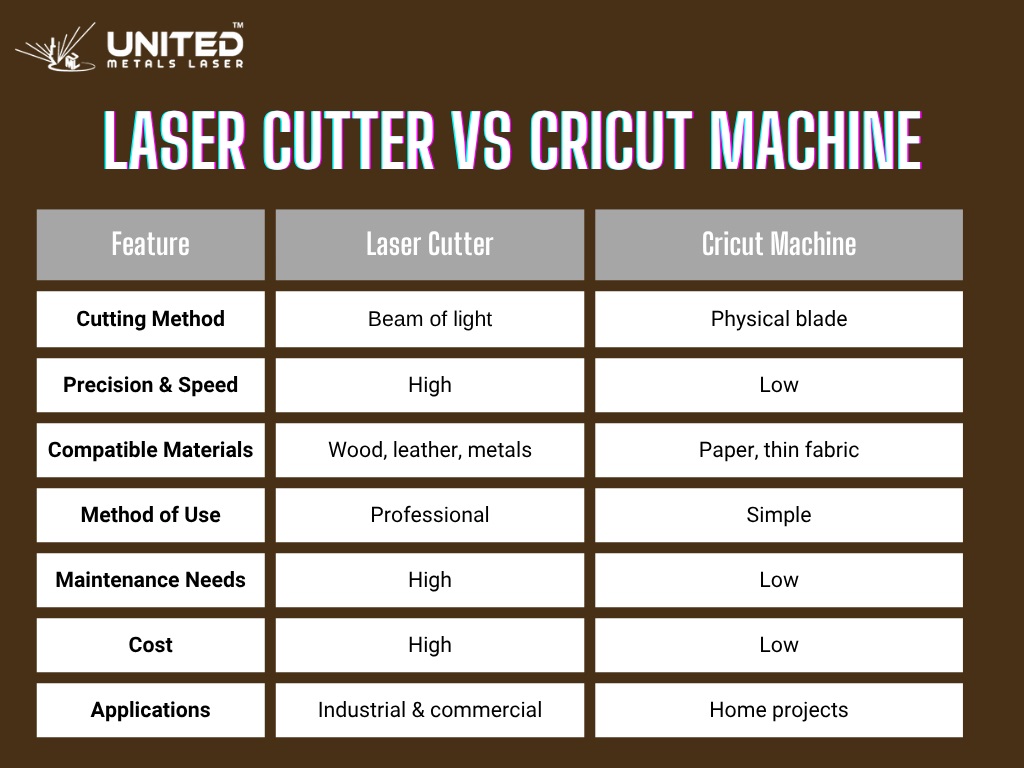

Laser Cutter vs Cricut: Comparing 5 Performance Elements

Now let’s compare the features and benefits of both to get a clear picture.

1. Cutting Technology

Laser Cutter: Uses a focused beam of light to penetrate even better and gives smoother edges. Also, its precision doesn’t dull over time or number of cuts.

Cricut: Uses a physical blade to carve out shapes, so, it only works for thin & soft materials. And it wears down or gets dull over time. Precision is slightly compromised too.

2. Material Compatibility

Laser Cutter: Deals with an extensive range, including wood, acrylic, metals, and even pipes or tubes. You can use laser for cutting fabric as well as wood. And it’s the only choice for complex & dense materials of industries.

Cricut: Best for thin & soft materials like vinyl, paper, cardstock and lightweight fabrics. It can’t handle the hard materials and that’s why has limited applications.

3. Precision of Cutting

Laser Cutter: Offers pinpoint precision, down to fractions of a millimetre. That’s how it can create more detailed, intricate & neat designs with sharp cuts. Hence, it can handle professional & commercial projects with more accuracy.

Cricut: Gives clean edges on soft materials but struggle with complex engravings or tougher materials. Plus, the sharpness of cut gets compromised on time.

4. Speed of Cutting

Laser Cutter: Blazing fast, especially while dealing with repeating patterns or bulk work. It can get the custom metal pieces done in a flash & suits the fast production times.

Cricut: Quick for simpler designs on light materials, but slows down while handling with complicated patterns. Speed is satisfactory but not optimal for commercial operations.

5. Applications

Laser Cutter: Suited to industrial signage, architectural models, metal plaques, precision components, and engraved logos for upscale businesses.

Cricut: Used for paper crafting, small vinyl projects, light fabric designs, personal crafts, and home-based artistic businesses.

Laser Cutter vs Cricut: What Do Usability Factors Say?

Now let’s discus the concerns of handling and access.

1. Ease of Use

Laser cutter machine requires training on safety and software to master settings and materials. But once you get the hang of it, it’s unstoppable.

While for Cricut, you just plug in, follow the software and let it do the rest. It suits to beginners who don’t have much know how of tech related stuff and want a simple and straightforward process.

2. Need for Safety Gear

Laser engraver and cutter needs protective eyewear and good ventilation. Extra safety measures like fire protection are required for worry-free cutting.

While cricut doesn’t demand any special gear. As it cuts with a regular blade, so, basic caution is enough.

3. Maintenance Needs

In case of cutter laser, more maintenance is needed to keep its beam as powerful and accurate as day one. E.g. lens cleaning, filter changes and regular checks.

On the other hand, blade and mats of cricut can be kept in good shape with regular cleaning the occasional replacement.

4. Cost

Laser is a bigger upfront investment, especially if you need it for industrial use. Even a small laser cutter comes with a high price tag but pays off with better working & long-term use.

Cricut is more affordable with the machine and accessories fitting into personal budget.

Should I Buy a Cricut or Laser Cutter?

If you’re a hobbyist or artist working with vinyl, lightweight paper or cards. You can make colourful designs, greeting cards and personalised gifts with cricut. It’s budget-friendly and super simple to use.

But if you deal with heavy duty & complex work for commercial purposes. Your projects need to cut through metal, thick wood or custom pipe shapes. Only a laser for cutting can help you with that. It’s faster and delivers professional-grade results.

Need Laser Cutters Australia with Professional Handling?

Work with United Metal Laser

Our expert team is ready to make your vision a reality. From laser cutting and architectural pieces to metal folding & pipe profiling. We deliver projects quickly, safely and always at the highest quality.

Just want a small logo design? Our laser cut mini can do that. Need something complex? No problem for our heavy machinery with experienced staff. Don’t have enough time? Still no issue. Our express option has you covered in 48 hours.

Let’s turn your ideas into real-world products!

FAQs

Can a laser cutter replace a Cricut?

A laser cutter can handle a wider range of materials and produce highly precise cuts. So, yes, it has the potential to replace a Cricut. However, for light crafting, cricut is still a more cost-effective option.

What are the disadvantages of laser cutting?

Laser cutting requires a higher upfront investment and needs a well-ventilated workspace for safe fume extraction. It also demands more maintenance, and the learning curve for software and safety can be steep for beginners.

Can you use laser cut files on Cricut?

Yes, you can use the same vector-based files (like SVG or DXF) on both Cricut machines and laser cutters. However, you need to adjust settings for blade depth or cutting order to get clean results on the Cricut.

What is the best laser cutter for home?

For home use, look for compact CO₂ laser cutters that can safely handle materials like wood and acrylic. They’re smaller, easier to maintain, and have enough power for small business or hobby projects.

How much does laser cutting cost?

The price for laser cutting depends on the project’s complexity, material type, and batch size. United Metal Laser offers competitive rates, with small jobs completed within days and larger jobs quoted promptly.

Are cheap laser cutters worth it?

Cheaper laser cutters are more tempting, but they can lack in power, precision, or speed. If you’re serious about your work, investing in a high-quality machine from a trusted company can give you reliable and consistent results.