Beginner Guide to 3D Laser Cutting: Process, Uses & Benefits

How these sleek car parts, custom metal signs, or futuristic furniture pieces are cut so precisely? Intricate shapes & neat designs, how they come into being?

That’s the magic of 3D laser cutting.

It’s not just another industrial buzzword, but a technology that took metalworking by storm. When you deal with manufacturing, architecture, or design, you continuously juggle between quality, time, and cost. All you need is an advanced & efficient manufacturing method.

And 3d laser cutter has enabled that. It is fast, consistent and deals with every curved surface or complex shape.

United Metals Laser is making waves with this tech. As a proudly Western Australian business, we combine advanced cutting technology with real-world problem-solving. From custom parts to big-batch production runs, we provide high-precision, fast-turnaround cutting solutions across Australia. If you're looking for Laser Cutting Perth wide that’s fast, accurate, and reliable—we’ve got you.

3D Laser Cutting: What is It?

3D laser cutting is a process that uses a high-powered laser to cut through materials. Not just in flat, straight lines, but in complex 3D forms. Unlike traditional cutting methods, laser cutting uses focused beams of light that can handle:

- 1. Tight corners

- 2. Odd angles

- 3. Tricky shapes

A 3D laser cutter can move in multiple directions: up/down, left/right, and even tilt or rotate. This flexibility allows it to cut around curved surfaces, tubes, and pre-formed parts.

- Need a hole at an angle on a round pipe? Easy.

- Want clean edge cuts on a bent metal sheet? No problem.

It reduces the need for manual labour, speeds up production & improves consistency. Plus, it’s fully programmable. Just plug in a 3D CAD file, and the machine gets to work with pinpoint accuracy.

How Do Cutting Lasers Work?

Laser cutters focus an intense beam of light, on a small area of material. The energy powered by electricity or gas is so concentrated that it melts, burns, or vaporises the material. Then, a high-pressure gas, like oxygen, nitrogen, or air, blows the molten material away. And a smooth & sharp-edged cut is made.

In 3D laser cutting machines, the laser head is mounted on robotic arms or multi-axis platforms. So, the beam can be aimed at precise angles and rotated around complex geometries. The result? Cuts that look like they were sculpted by a sci-fi robot surgeon.

Our fibre lasers offer higher power density, less maintenance, and crazy-fast cutting speeds. That's how we keep up with both high-volume orders and last-minute express jobs.

Types of Laser Cutters

Yup, there are many types of cutters, not just one. The common laser cutters laser cutters Australia includes:

1. CO₂ Lasers

One of the earliest and most widely used types of laser cutters. These systems generate a laser beam by electrically exciting a gas mixture. Like carbon dioxide, nitrogen, or helium.

CO₂ lasers are effective for non-metallic materials such as plastic, wood, acrylic, and leather. They're affordable and versatile. So, they are the obvious choice of craft and industrial applications.

However, thicker metals or reflective surfaces cause their beam to deflect & compromise cutting quality.

2. Neodymium Lasers

They use a crystal-based laser medium to create a highly concentrated light beam.

These lasers are capable of very fine, precise cuts. Hence, they are used in applications that require high energy densities. E.g. drilling or engraving hard metals and ceramics.

While powerful, neodymium lasers come with higher operational costs and are slower than fibre lasers. They’re ideal for specialised tasks where precision is required, but not suitable for bulk metal cutting.

3. Fibre Lasers

The most advanced technology in modern fabrication is the fibre laser.

They generate a powerful beam using fibre-optic cables infused with rare earth elements. Resulting in efficient systems with less maintenance needs & longer operational life than their counterparts.

Their high-speed performance and ability to handle a wide range of metals. E.g. steel, aluminium, copper, and brass. That’s why, they are the backbone of modern 3D laser cutting machines. Be it a flat sheet metal or intricately shaped pipes.

2D Laser Cutting vs 3D Laser Cutting: What’s the Big Deal?

You’ve probably heard of 2D laser cutting as the OG of the laser world. It slices flat surfaces like sheet metal in two dimensions: X and Y. Simple, effective, and perfect for flat parts.

3D laser cutting, on the other hand, adds the Z axis, plus rotation and tilt. That gives it the superpower to work on curved, bent, or pre-formed objects.

|

Feature |

2D Laser Cutting |

3D Laser Cutting |

|

Axes of movement |

X & Y |

X, Y, Z + tilt/rotate |

|

Ideal for |

Flat sheet metal |

Tubes, formed parts, complex angles |

|

Setup needs |

Flat material only |

Works with irregular shapes |

|

Flexibility |

Limited |

Maximum design freedom |

|

Best use case |

Simple brackets, flat parts |

Automotive parts, custom pipes |

This is why we’ve invested in 3D laser cutting machines. So, our customers can enjoy more flexibility, less prep, and faster delivery.

Benefits of Laser Cutting: Why It’s Worth the Hype?

Still wondering why laser cutting technology is taking over? Here’s what makes it unbeatable:

- 1. Extreme Accuracy: We’re talking tolerances as tight as ±0.1mm. No manual cutting tool can match that.

- 2. Smooth Finishes: No rough edges, no burrs, and very minor need for finishing.

- 3. Less Waste: Because of the precision, there's minimal scrap.

- 4. Speedy Production: Especially for high-volume jobs. Our 48-hour express option? Total lifesaver.

- 5. Design Versatility: Custom logos, patterns, or industrial-grade components, it can handle them all.

At United Metals Laser, we mix precision with performance. If you need a single prototype or a thousand pieces, our machines deliver consistently clean cuts.

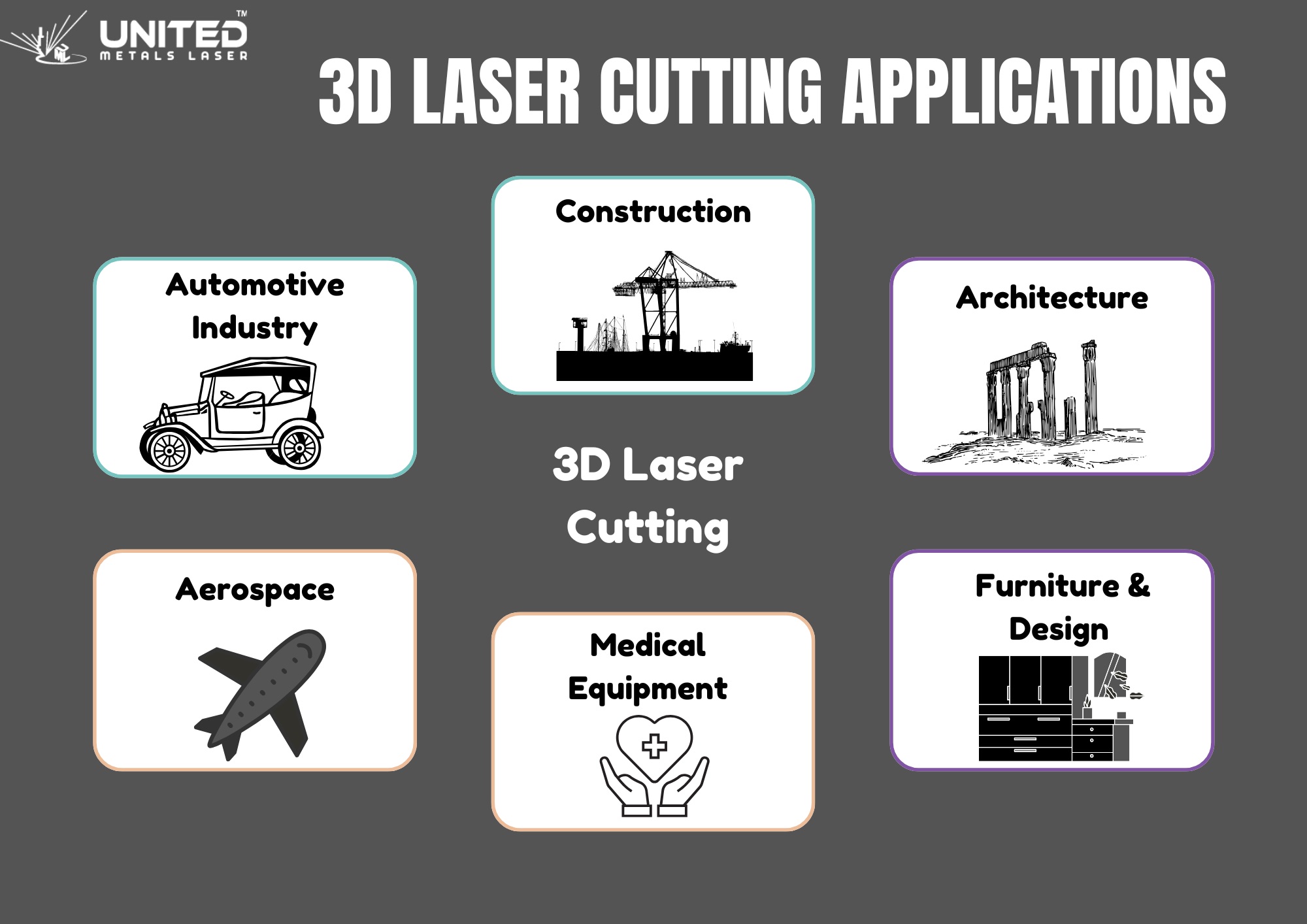

Real-World Uses: Where You’ll Find 3D Laser Cutting in Action

Let’s zoom out and see the total scope of 3D laser. How any industries are getting advantage of this advanced technology? Spoiler alert: pretty much everyone.

- 1. Automotive: From chassis components to exhaust systems, clean & strong cuts are non-negotiable for every vehicle part.

- 2. Architecture: Fancy facades, decorative metal screens, signage, everything needs proper & neat shape.

- 3. Construction: Metal brackets, framing elements, and support structures.

- 4. Medical: Cutting tools, precision instruments, and equipment components.

- 5. Furniture & Design: Metal legs, frames, art pieces & sleek designs.

- 6. Aerospace: Ultra-lightweight parts with precision edges that won’t fail mid-flight.

Need strength, style, and precision? 3D & 2D laser cutting is the answer. It is changing the industrial picture of Aussie setups fast.

Why 3D Laser is the Future of Australia Laser Cutting?

In today’s work routines, no one has time to mess around with clunky old methods. Like everything else, Laser cutters Australia are also being upgraded, and companies are turning to smarter & leaner systems. Now:

Here’s what’s changing:

- 1. Customers expect same-day quotes and next-day delivery.

- 2. Parts need to be lighter, stronger, and better-looking.

- 3. Industries need suppliers who can think and move fast.

3. That’s why 3D laser is the only way forward.

Searching for 2D and 3D Cutting Experts in WA?

Work With United Metals Laser

From Laser Cutting Perth to nationwide delivery, United Metals Laser brings you industry-leading solutions using the latest 3D laser cutting machines.

If you’re creating architectural wonders or producing functional industrial parts. Our team can assist you in delivering sharp results, quick turnarounds, and total support. Let us take your project to the next level with:

- 1. World-class equipment

- 2. 27+ years of combined expertise

- 3. Commitment to quality that shows in every cut

Ready for precision? Let’s make it happen.